Drives for propeller shafts

More freedom for engine movement, less freedom for vibration

The VETUS DRIVE (Type VDR) is a combination of a self-aligning thrust bearing and a double-acting constant velocity joint. The propeller thrust is absorbed by the inbuilt thrust bearing, allowing the engine to be set up on softer mountings: this results in lower vibration and transmitted noise. The VDR is made of black passivated steel and high-performance rubber. This heavy-duty VDR has been tested under the toughest conditions and is suitable for maximum thrust up to 24,000N.

Specifications

- VDR6 is available for shaft diameters of 50, 60 or 70mm

- VDR2 and 4 are available for shaft diameters of 25, 30, 35, 40, 45 or 50mm

- Interchangeable with other well-known models

- Durable design with long lifetime

Use the VETUS Drive Selector to choose your VETUS drive!

VDR221355

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR221354

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR221305

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR221304

VETUS VDR 2, constant-velocity joint 21, shaft 30mm, 4'' flange

VDR215355

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR215354

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR215305

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR215304

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR215255

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR215254

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR210305

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR210304

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR210255

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

VDR210254

Advantages conferred by this drive with its integral thrust bearing include more freedom for engine movement plus the reduction of onboard vibration and noise.

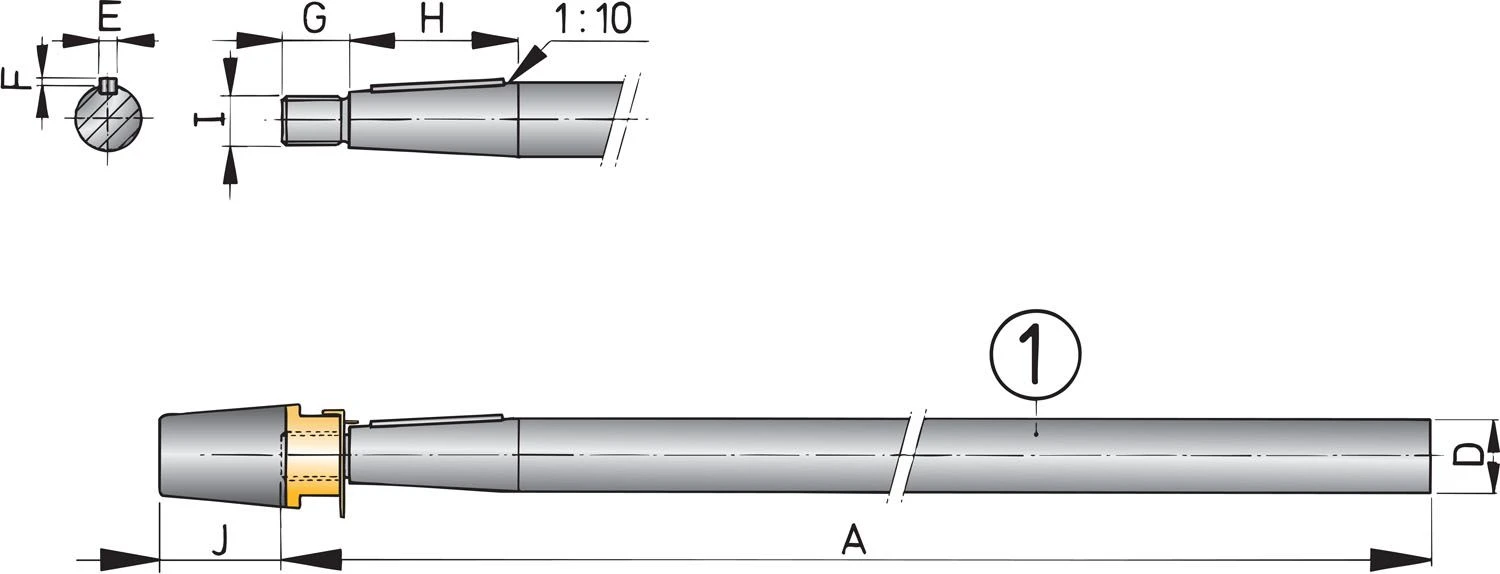

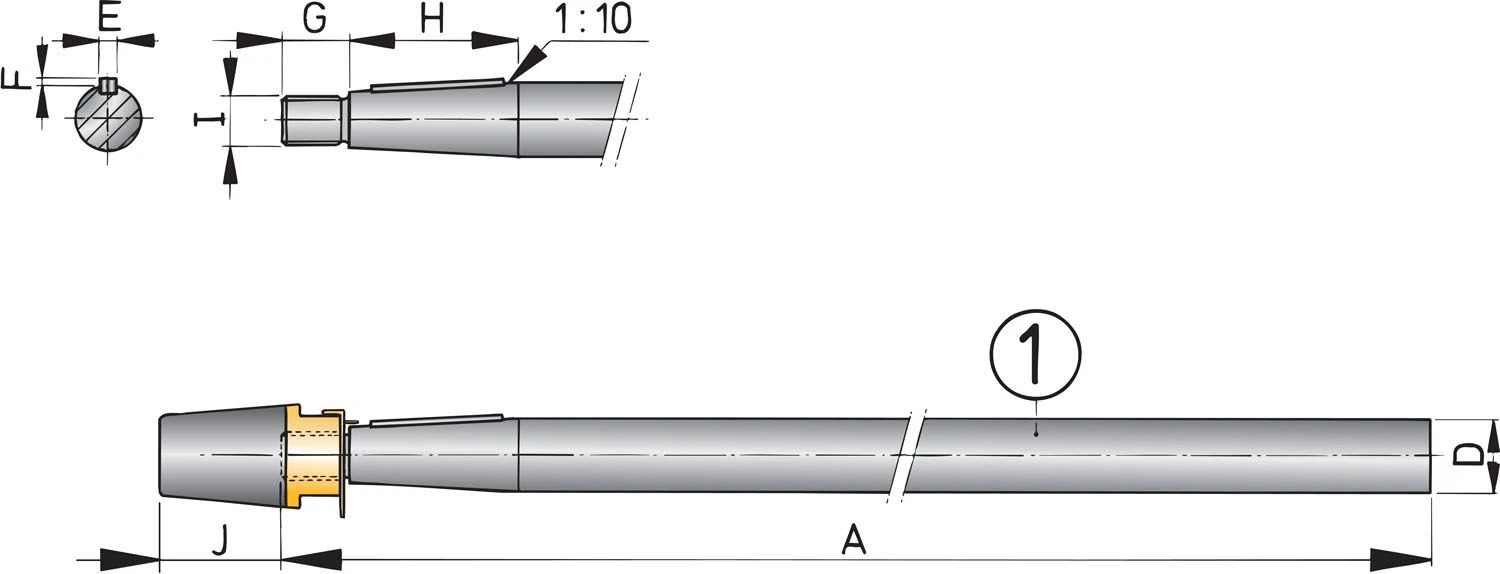

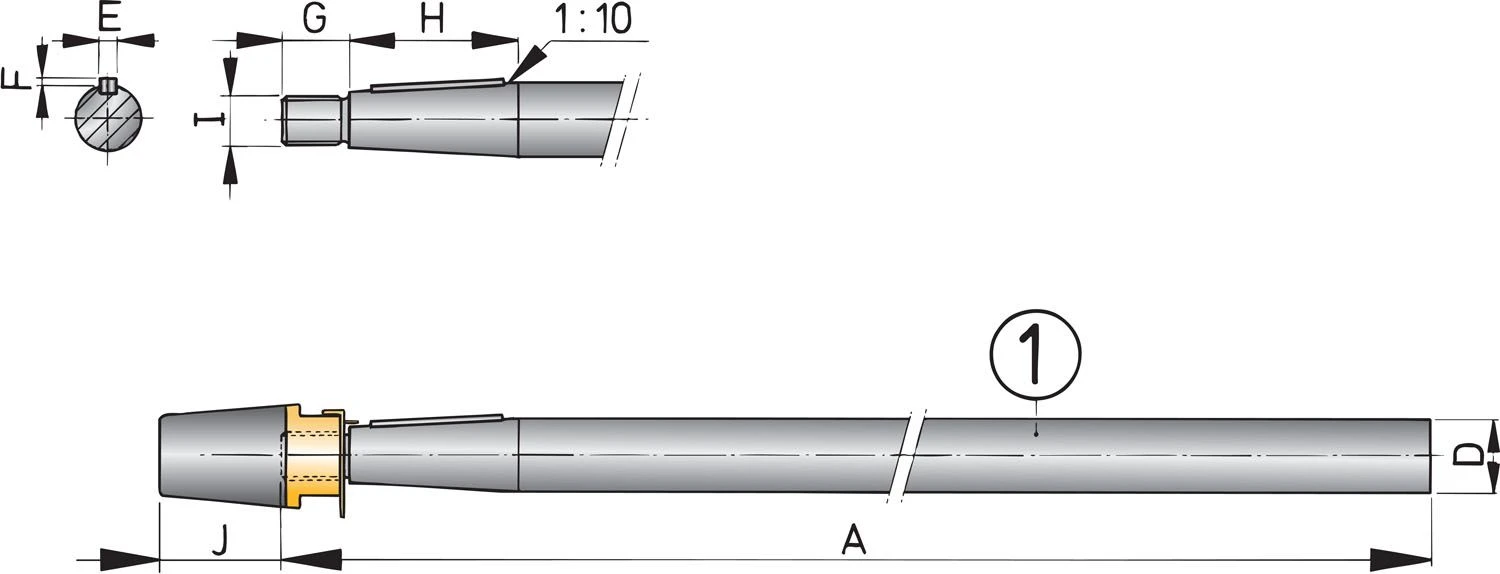

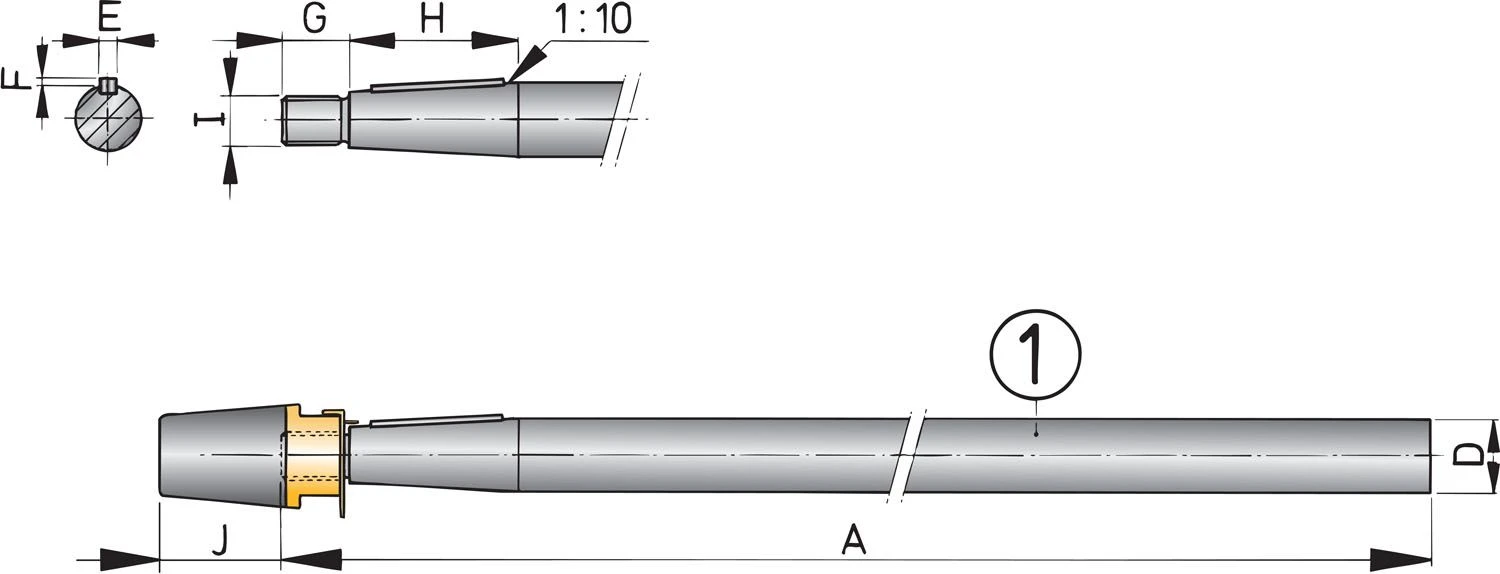

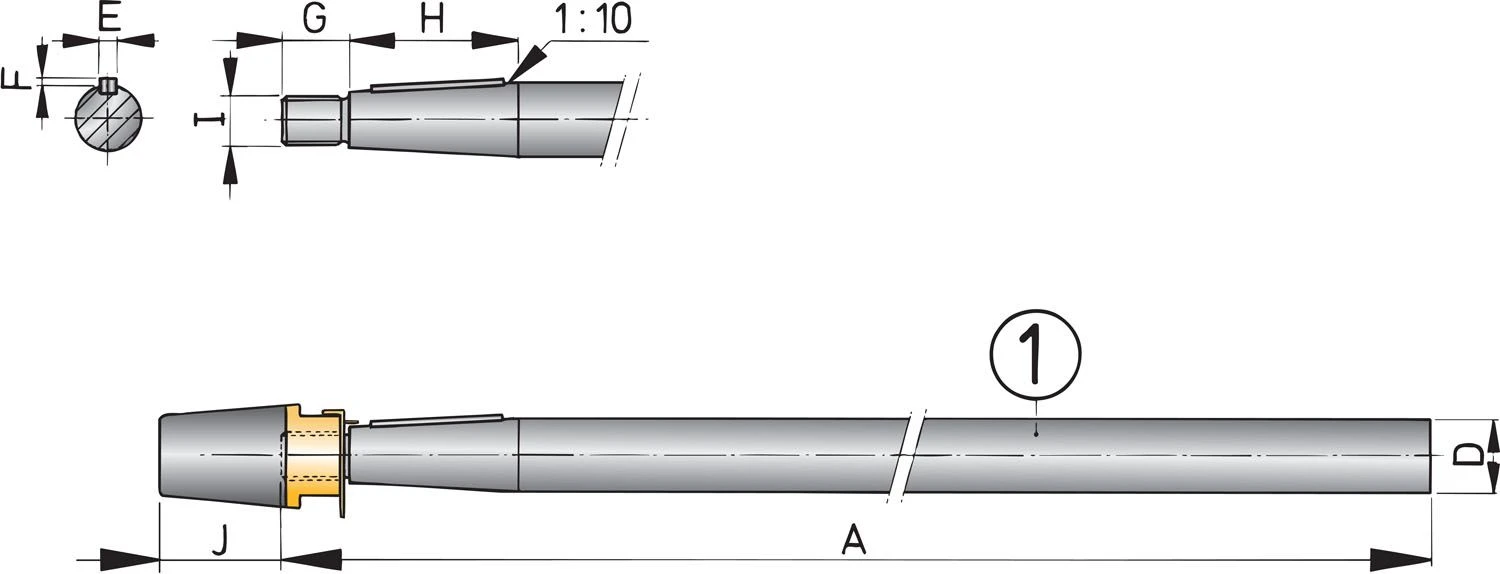

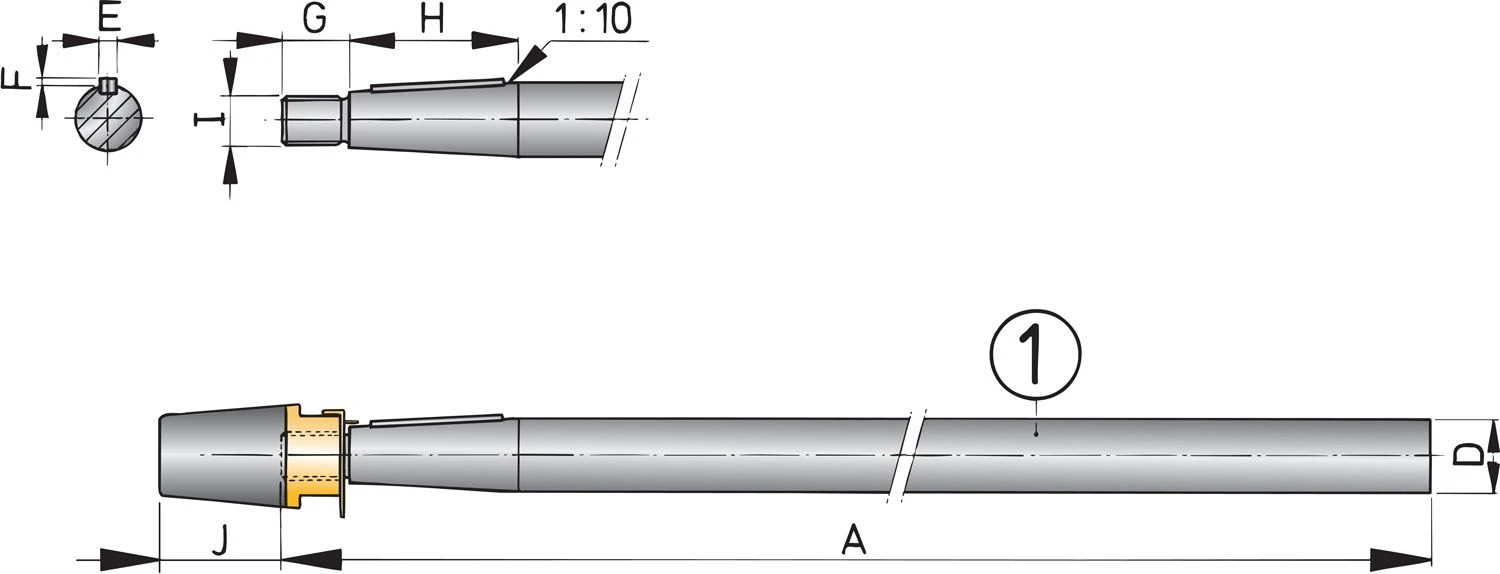

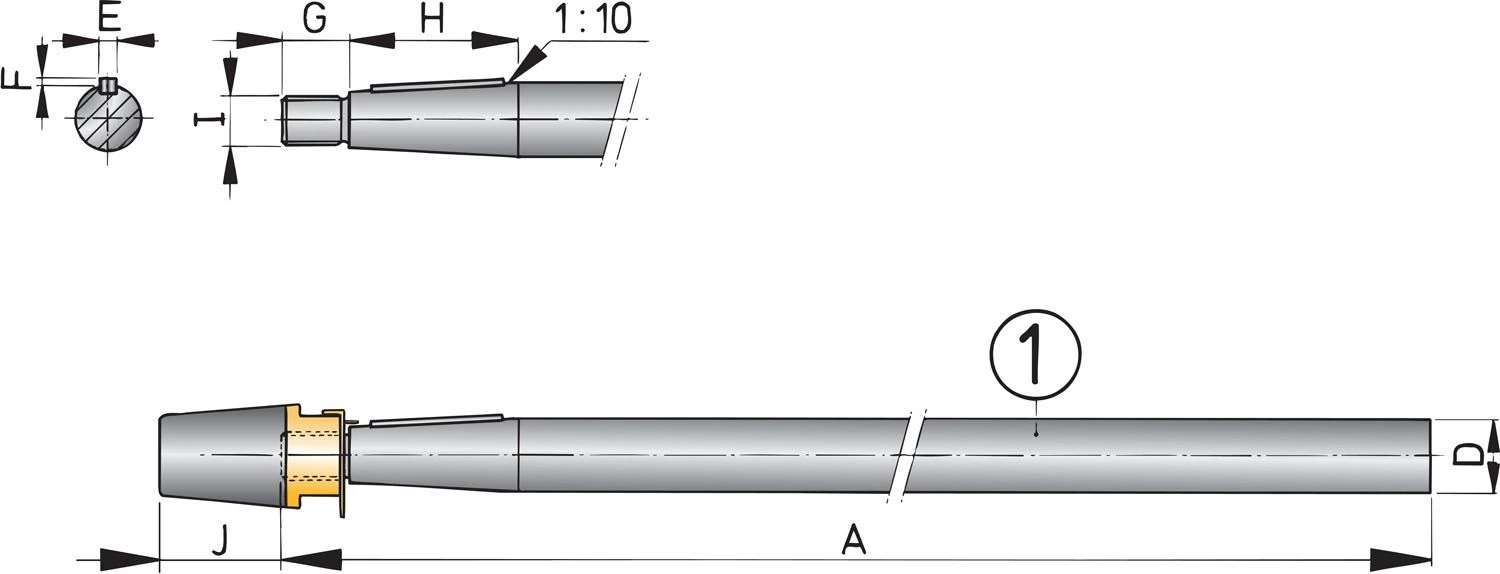

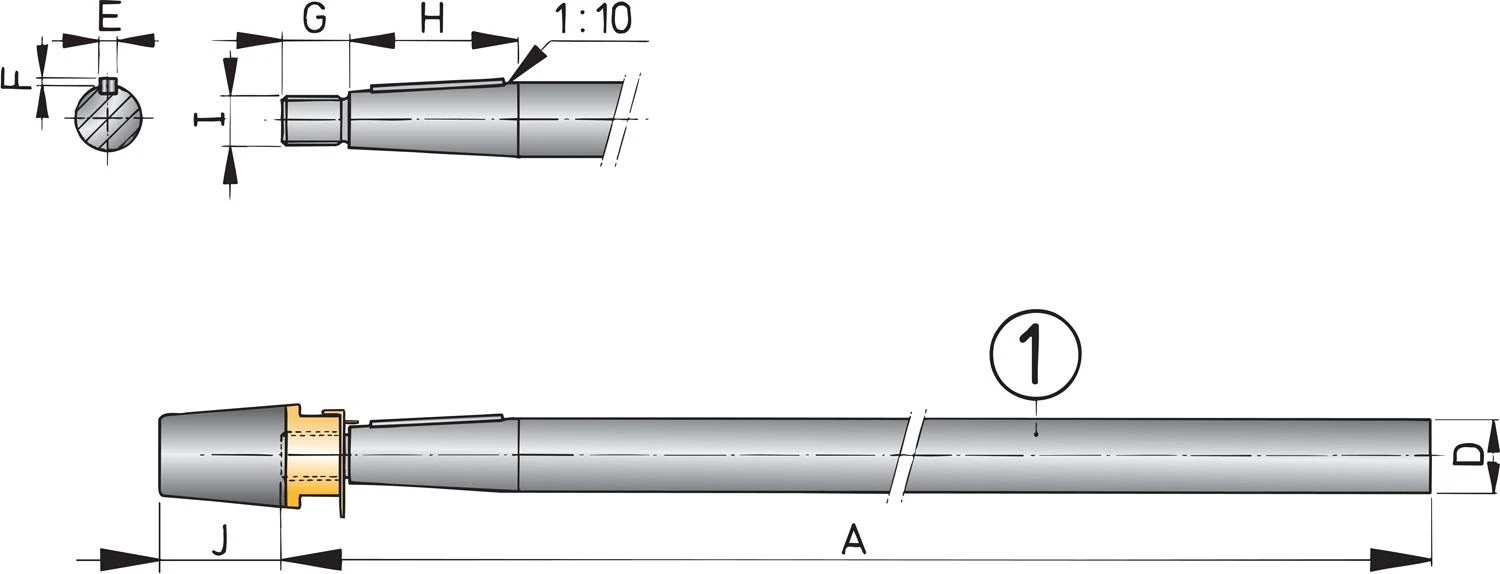

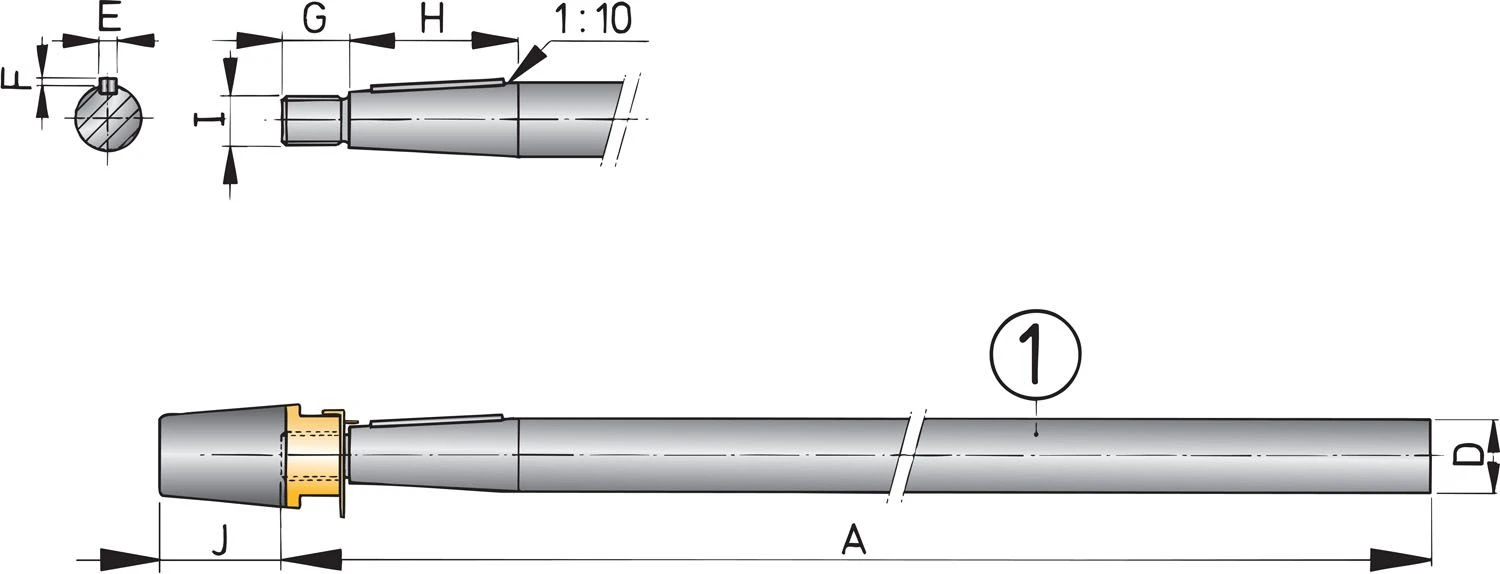

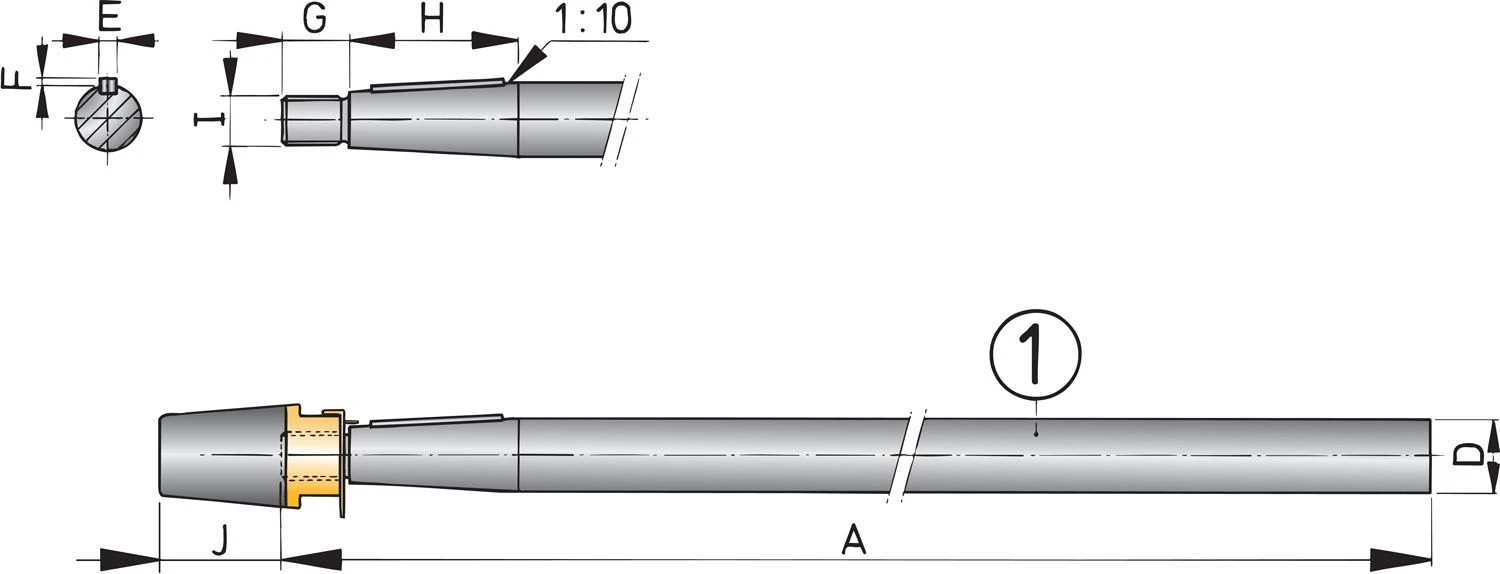

SA35/3000

One shaft end is machined with a 1:10 taper and a keyway as standard. Matching key, tab washer and propeller nut with integrated zinc anode also supplied.

SA35/2500

One shaft end is machined with a 1:10 taper and a keyway as standard. Matching key, tab washer and propeller nut with integrated zinc anode also supplied.

SA35/2000

One shaft end is machined with a 1:10 taper and a keyway as standard. Matching key, tab washer and propeller nut with integrated zinc anode also supplied.

SA30/3000

One shaft end is machined with a 1:10 taper and a keyway as standard. Matching key, tab washer and propeller nut with integrated zinc anode also supplied.

SA30/2500

One shaft end is machined with a 1:10 taper and a keyway as standard. Matching key, tab washer and propeller nut with integrated zinc anode also supplied.

SA30/2000

One shaft end is machined with a 1:10 taper and a keyway as standard. Matching key, tab washer and propeller nut with integrated zinc anode also supplied.

SA30/1500

One shaft end is machined with a 1:10 taper and a keyway as standard. Matching key, tab washer and propeller nut with integrated zinc anode also supplied.

SA25/3000

One shaft end is machined with a 1:10 taper and a keyway as standard. Matching key, tab washer and propeller nut with integrated zinc anode also supplied.